Circular Manufacturing

Our daily lives are supported by various artifacts. We are able to perform day-to-day tasks through the functioning of various products and facilities, from those that support spaces such as homes, offices, shops, and factories to those that support networks such as power, water, transport, and communications systems. From the resource consumption perspective, a huge amount of resources is used to produce these artifacts.

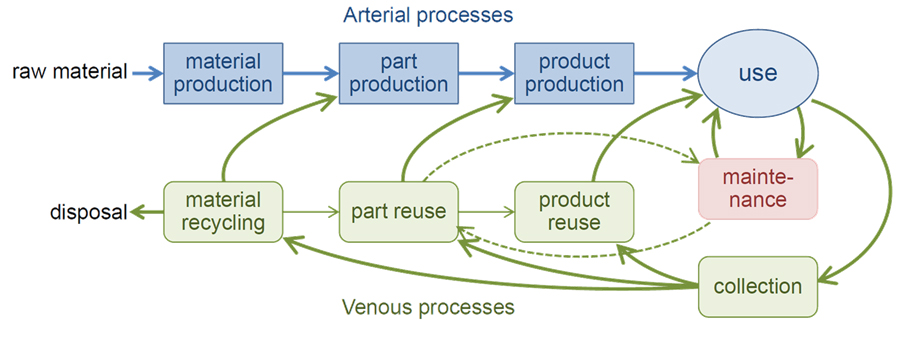

In light of the growing problems of resource availability and environmental damage, finding ways to reduce the environmental impact and resource consumption required to produce these artifacts has become an urgent issue for the manufacturing industry. Circular Manufacturing is an attempt to cope with his this problem and is rooted in the concept of circular economy where movement of products and services is in closed loops or ‘cycles’. Circular Manufacturing is where the industry is regenerative in nature, retaining and rechanneling as much value as possible of products, parts and materials. It is based primarily on 3R viz., Reduce, Reuse and Recycle.